Experts in Simulation Engineering

We are a pioneer company in the application of CAE and simulation solutions in a variety of industries since 2003

Service

Extensive experience in simulation engineering

Based on an extensive background of more than 15 years, we deliver leading advanced simulation, engineering and consultancy FEA/CFD services around heat transfer and process equipment, non-conventional structures, high temperature piping or ducts systems and a wide range of equipment and structures

FEA - Finite Elements Analysis

The finite element method (FEM) is a numerical technique used to perform finite element analysis (FEA) of any given physical phenomenon.

CFD - Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) is one of the branches of fluid mechanics that uses numerical methods and algorithms to solve and analyze fluid flow problems.

CHT - Conjugated Heat Transfer

The Conjugate Heat Transfer (CHT) analysis type allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them.

Our value proposal

Cost savings

Manufacturing cost savings (Lean Manufacturing)

Design and optimization

Saving materials and reducing weights

Definition of lightweight materials

Definition of high-strength materials

Definition of high durability materials

Safety & Reliability

Structural integrity analysis

Stability analysis

and / or overturn

Vibration analysis

Modal analysis

(determination of

natural frequencies)

Dynamic analysis

(harmonics,

spectral,

dynamic, PSD)

Simulation of

welding processes

Detection &

anticipation of failures

Evaluation of the useful or remaining life

Fitness For Service FFS Analysis (Aptitude to Service)

Root cause analysis (failure detection and evaluation)

Location and identification of critical points

Fatigue analysis and Creep analysis.

Mechanical analysis of the fracture

Definition of plan of corrective measures

Predictive and corrective maintenance.

Simulation with digital models (Digital Twin)

Time to market

Development of parameterizable designs

Development of modular designs

Lean philosophy

Implementation of agile systems and optimization of design rework

Some of our solutions

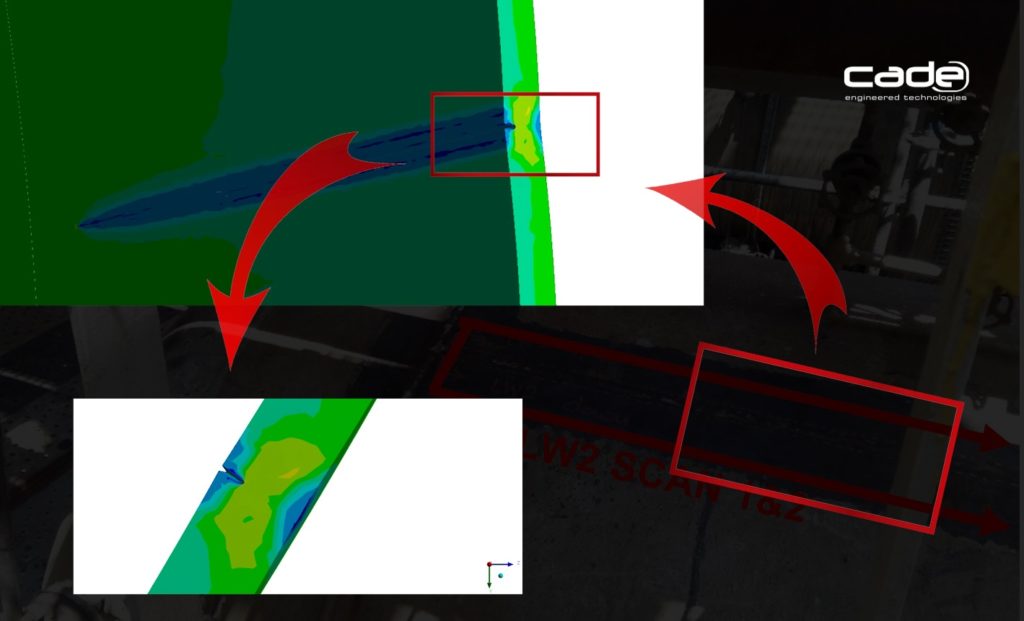

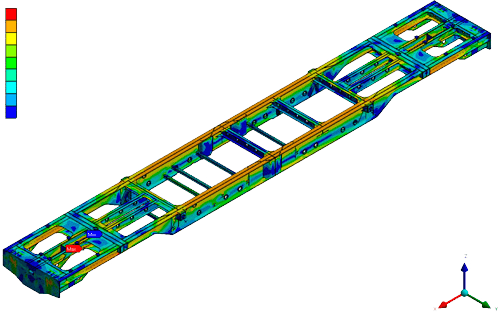

FEM Analysis

Finite Elements analysis

The finite element method (FEM) is a numerical technique used to perform finite element analysis (FEA) of any given physical phenomenon.

It is necessary to use mathematics to comprehensively understand and quantify any physical phenomena, such as structural or fluid behavior, thermal transport, wave propagation, and the growth of biological cells. Most of these processes are described using partial differential equations (PDEs). However, for a computer to solve these PDEs, numerical techniques have been developed over the last few decades and one of the most prominent today is the finite element method.

- Thermal / Structural Transient Analysis

- Dynamic Analysis (modal, harmonic, spectral, PSD, explicit, (…)

- Non-Linear Analysis

- Life Assessment, fatigue, and Creep Analysis

- Fracture mechanics simulation

- CHT – Conjugated Heat Transfer Analysis

- Welding process simulation and PWHT analysis

- Composite, gasket, and other nonmetallic materials

- Topology Optimization

- MBD – Multibody Dynamics

- APDL Programming – Customized Analysis Tools

Successful Projects

Quality Customers

Countries

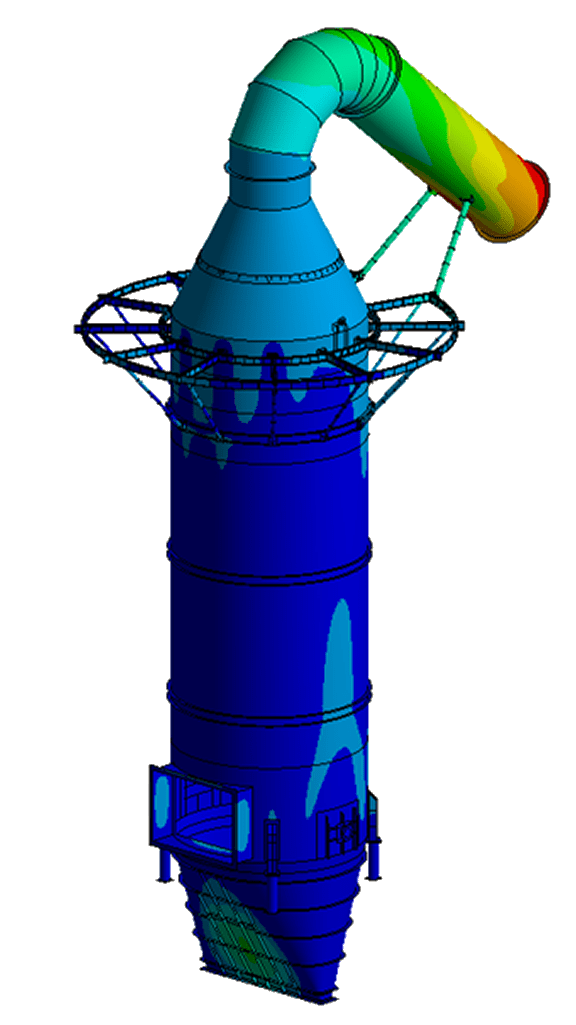

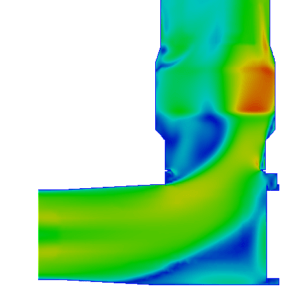

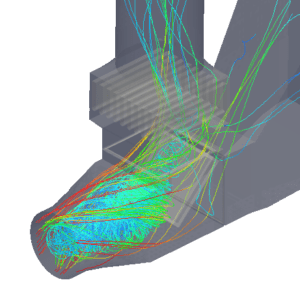

CFD Analysis

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) is one of the branches of fluid mechanics that uses numerical methods and algorithms to solve and analyze fluid flow problems.

Computers are used to perform millions of calculations required to simulate the interaction of liquids and gases with complex engineering projected surfaces. Even with simplified equations and high-performance supercomputers, only approximate results can be achieved in many cases.

Continuous research, however, allows the incorporation of software that increases the calculation speed as well as decreases the margin of error, while allowing the analysis of increasingly complex situations such as transonic fluids and turbulent flows. The verification of the data obtained by CFD is usually carried out in wind tunnels or other physical scale models.

- Multi-phase Flows

- FSI – Flow-Structure Interaction

- Heat Transfer and Radiation

- Internal Flows Behavior

- Turbulence Modeling

CHT

Conjugated Heat Transfer

The Conjugate Heat Transfer (CHT) analysis type allows for the simulation of heat transfer between solid and fluid domains by exchanging thermal energy at the interfaces between them. Typical applications of this analysis type exist as, but are not limited to, the simulation of heat exchangers, cooling of electronic equipment, and general-purpose cooling and heating systems.

The CHT approach has an advantage over FE thermal analyses in that wall heat transfer coefficients and their local variations on surfaces are directly calculated within the model rather than based on simplified empirical calculations. The CHT approach therefore has benefits for those applications where heat transfer is either non-uniform or difficult to calculate empirically.

Our news

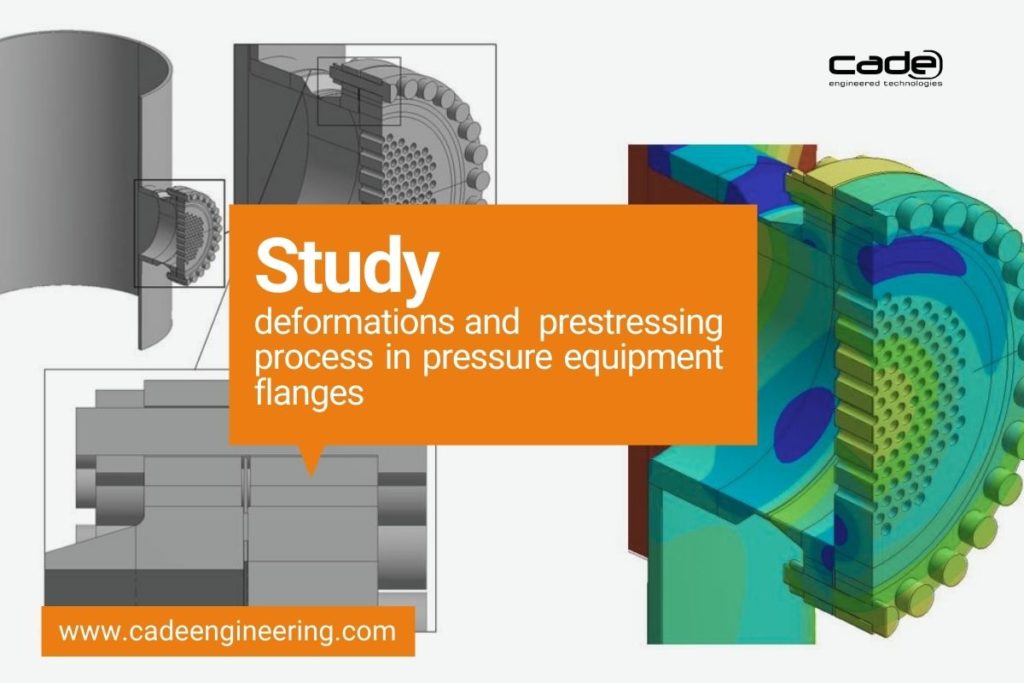

Study of deformations and the prestressing process in pressure equipment flanges

The flanged joints of pressure equipment can show deformations due to the bolt tightening process, or being generated later during service. The appearance of this type of problem may…

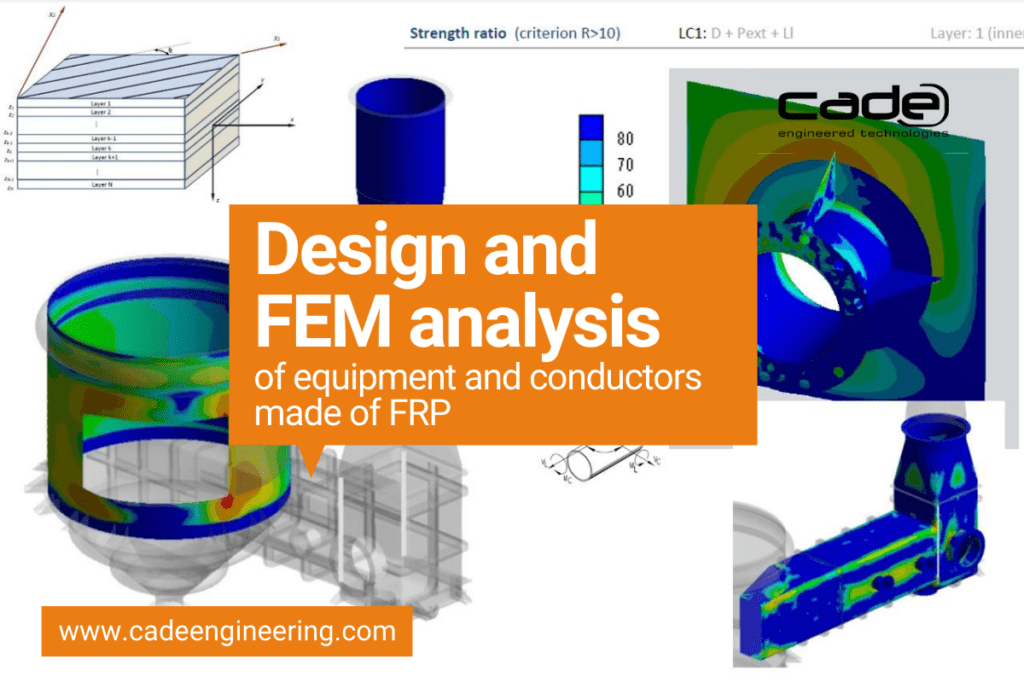

Design and FEM analysis of equipment and conductors made of fiber reinforced plastic (FRP)

There are many sectors (chemical and process industry, naval, aeronautical or food sector) and industrial applications in which it is necessary to design and validate…

Fitness for service procedures for cracks like flaws

During the life cycle of many pressure vessels arise the necessity to maintain them in service after detecting crack-like flaws or delamination. For that, there…