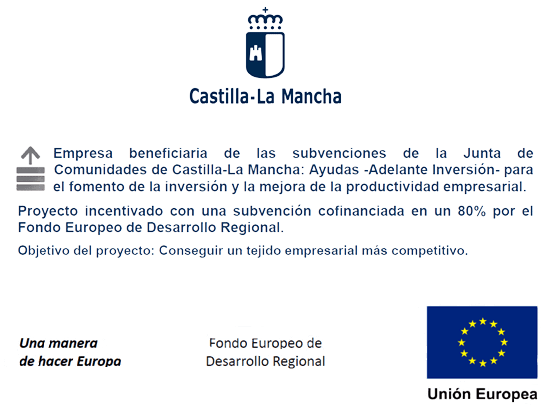

Study of deformations and the prestressing process in pressure equipment flanges

The flanged joints of pressure equipment can show deformations due to the bolt tightening process, or being generated later during service. The appearance of this type of problem may mean that the equipment is not suitable to continue with the operation, with the consequent economic impact that would entail a stop, repair or replacement of the affected components. Through FEA simulation […]

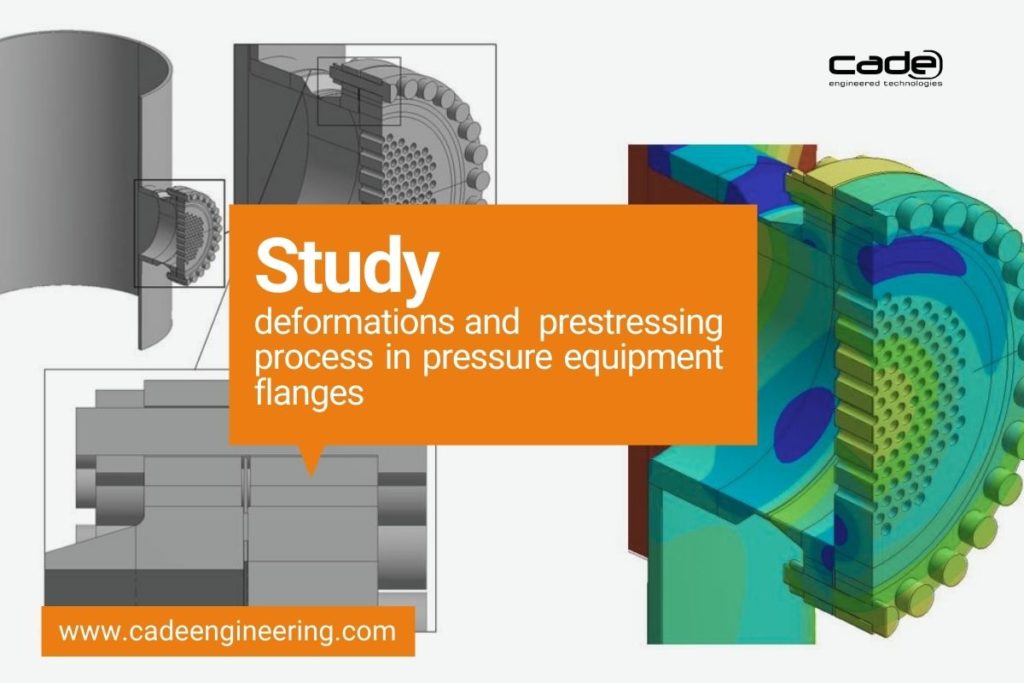

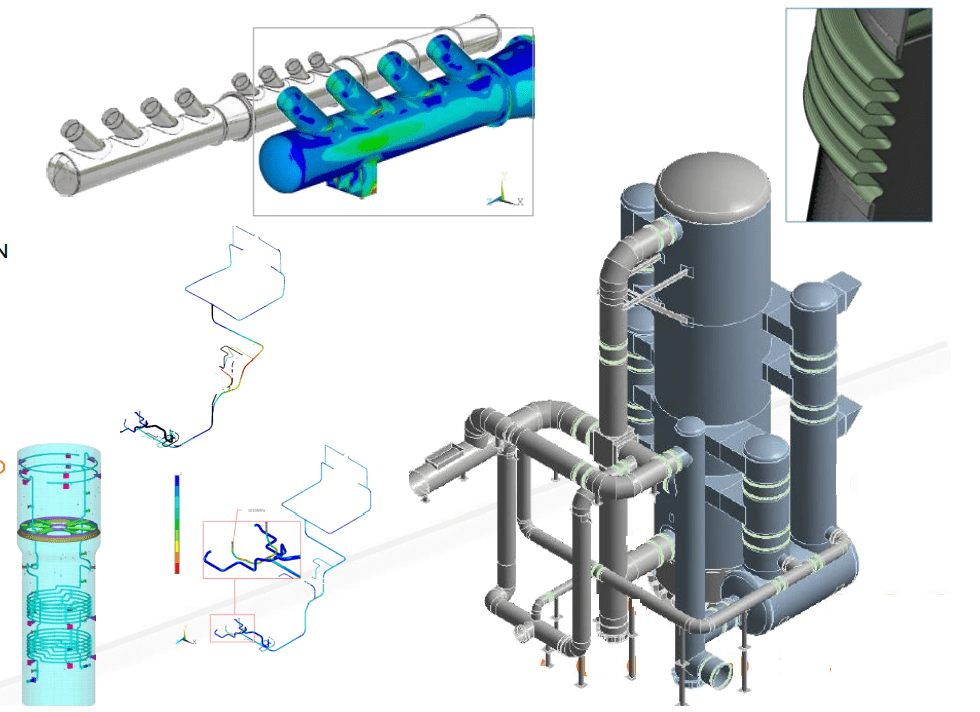

Design and FEM analysis of equipment and conductors made of fiber reinforced plastic (FRP)

There are many sectors (chemical and process industry, naval, aeronautical or food sector) and industrial applications in which it is necessary to design and validate equipment made with special materials (FRP- Fiberglass Reinforced Plastic), due to to the special corrosion resistance requirements for which they have to provide service. This is the case of pressure […]

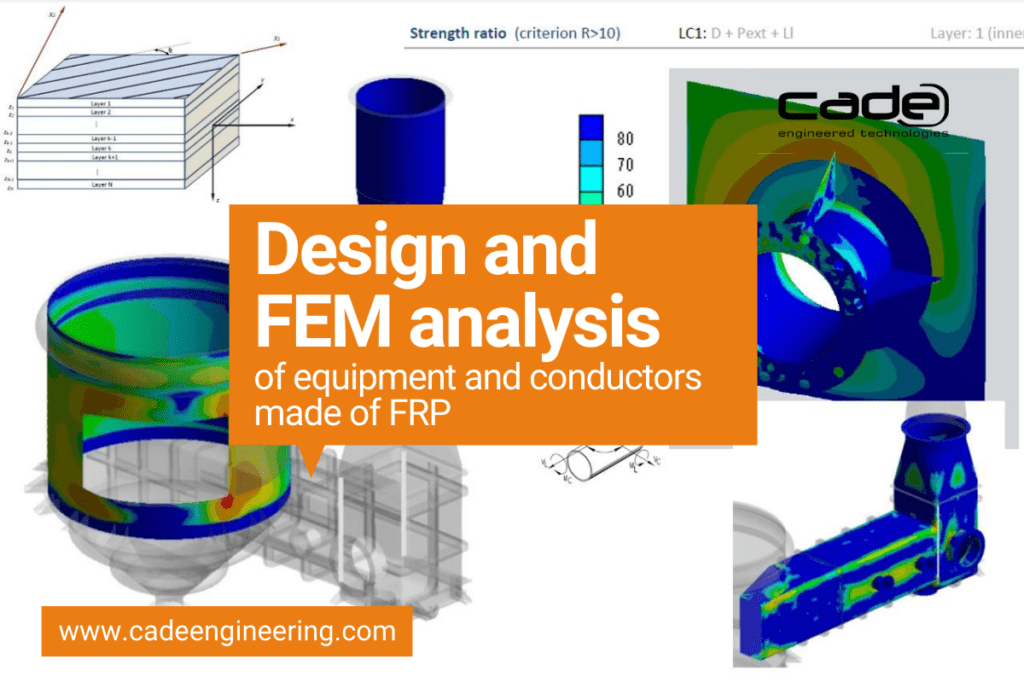

Fitness for service procedures for cracks like flaws

During the life cycle of many pressure vessels arise the necessity to maintain them in service after detecting crack-like flaws or delamination. For that, there are some methodologies that allow establishing a quantitative judgment about if it is possible to safely operate this equipment and also determine its remaining life until it must be repaired […]

STRESS ANALYSIS OF PIPES WITH RATIO D / t> 100

On certain occasions, during the development of projects where large diameter pipes are involved, scenarios arise in which the diameter (D) / thickness (t) ratio is higher than 100. It is common to find this situation in systems with large diameter pipes that work at low pressure, in which the calculated thickness due to the […]

CFD analysis of heat recovery boilers– HRSG

Computational Fluid Dynamics (CFD analysis) simulation of HRSG Boilers turns out to be a powerful engineering methodology in order to determine an optimal design to achieve maximum efficiency and avoid future operation issues, (such as incorrect mixing ratio, asymmetric burner performance, among others.). This type of simulations allows to analyze the behaviour of the chemical […]

Fitness for Service – Alternatives for equipment validation

Boiler and pressure equipment manufacturers face everyday strict design and manufacturing requirements to supply heat exchangers, pressure vessels or process equipment. The recognized international design and manufacturing codes that are prescribed for this type of equipment (ASME VIII Div. 1 & 2, EN13445, AD2000, etc.) specify those tests, trials, inspections and quality controls to be […]

Introducción, clasificación y diseño de intercambiadores de calor tipo TEMA

TEMA es el conjunto de normas y estándares más habitual empleado por diseñadores, fabricantes y usuarios para la fabricación y el diseño de intercambiadores de calor.

Brief introduction to TEMA HEAT EXCHANGERS design and selection

TEMA Standards are worldwide accepted as the authority on shell and tube heat exchangers design and manufacturing. These standards are the most commonly used in a wide range of industries throughout the world: refineries, oil and gas, power generation, etc.

PV Structures: beyond structural design

The relevance of solar structures is growing in the investment of PV solar plants due to many factors related to the PV market evolution: tendency towards multi-Megawatt plants, global increased of the competition and new emerging markets, and overall drastic drop of prices on solar panels.

Estructuras fotovoltaicas: más allá del diseño estructural

Los costes de fabricación, montaje y mantenimiento de estructuras fotovoltaicas tienen hoy un peso fundamental en la inversión total de una planta de generación solar fotovoltaica.