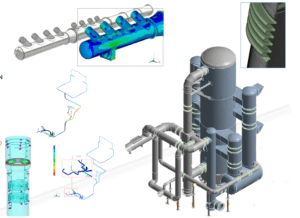

Computational Fluid Dynamics (CFD analysis) simulation of HRSG Boilers turns out to be a powerful engineering methodology in order to determine an optimal design to achieve maximum efficiency and avoid future operation issues, (such as incorrect mixing ratio, asymmetric burner performance, among others.).

This type of simulations allows to analyze the behaviour of the chemical species that intervenes in the combustion process without the need to carry out expensive empirical test or prototypes. Thus, optimal design is achieved in a more efficient manner. Time and development costs are drastically reduced from early design stages.

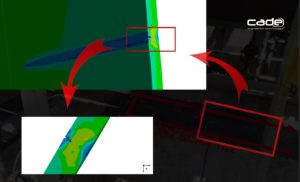

The simulation of the combustion process allows to determine an optimal geometry and configuration of burners together with the rest of the auxiliary elements which are meant to direct the flow, by studying the phenomena of vortex shedding, mixing of chemical species or velocity fields.

CADE counts on a multidisciplinary team of engineers with extensive experience in simulating combustion processes and fluid mechanics, using advanced CFD analysis simulation tools. CADE offers a wide range of services and capabilities aimed to technically support equipment Supplier, plant Operators and Owners by providing solutions along both design and operation phases.